Manufacturing & Engineering

Our experienced engineering resources ensure your product will be manufactured precisely all the way through to completion. C4 Manufacturing and Applications Engineers begin with a detailed examination of your entire project, upfront. They analyze drawings and specifications for manufacturability and determine where efficiencies might be gained to save you time and money. We utilize an array of world‐class CAD and CAM system software to accept and process your initial concepts and drawings.

Our services also include design assistance, material selection, weld‐distortion shrinkage calculations, and application of proper weld symbols.

Fabrication

The vertical integration of our engineering services with C4’s precision manufacturing services helps prevent time‐wasting communication stop points for clarifications and can dramatically reduce wait times between project steps. We have a well‐equipped fabrication and machining shop able to handle part production for a wide variety of pre‐ and post‐welding processes.

C4’s fabrication and machining services rival dedicated shops in the abilities and scope of services. We can eliminate your need for separate specialized vendors – and the time spent on shipments – with both critical‐grade welding capabilities and precision machining and fabrication services under one roof.

- Multiple high‐capacity overhead cranes for material movement between bays

- Oversized door truck access to fabrication and machining bays

- Sheet and plate metal rolling, shearing and braking

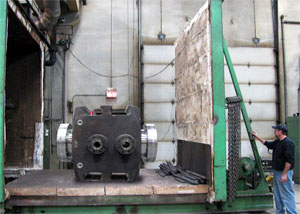

- Large part stress relief furnace

- CNC shape cutting, plasma & oxy‐fuel

- Cranes in multiple bays up to 40T

- 12′ x 16′ x 12′ Sandblast booth

- 800+ sq. ft stress-relieving furnace

- 10’ x 45’ CNC plasma cutting table

- Machine Shop

- Plate Rolls for 1” x 10’ Material

- Rotate Tables 75T and Positioners 30T

Coating & Blasting

C4’s capabilities to not only engineer, draft, assemble, weld and machine your project, but apply most any finish the job requires to meet your specific project requirements, is what sets us apart. We will ensure your project runs smoothly from your initial call through project completion.

We employ experienced applicators/painters who will complete your project by priming, color coating, and top coating to your company’s specified requirements whether it requires Urethane, Polane, Epoxy or Direct to Metal (DTM) coating or a specific RAL, Pantone or Universal Color Code; and can provide most any finish your project specifies.

Prior to the application of the coating, surface preparation will be given careful consideration. At C4 we have the capabilities to grit blast carbon steel, or blast Stainless Steels with either Aluminum Oxide or Coal Slag. We also have the ability to phosphorus wash. Our surface preparation will ensure the proper adhesion profile or SSPC-SP value is achieved for the coating to adhere properly.

We value your projects as much as you do and go the extra mile to ensure the highest quality standards. We have ISO procedures in place to ensure this as well as a Paint Inspection Form that will give you all the data recordings you may require including Wet and Dry Film Mil Readings, Gloss Meter Readings, Relative Humidity Readings, and more. C4 is willing to provide you with the required documentation in order to show compliance to you and your customers’ specifications.

We apply some of the highest quality coating systems and products

Additional Services

C4’s fabrication and machining services rival dedicated shops in the abilities and scope of services. We can eliminate your need for separate specialized vendors – and the time spent on shipments – with both critical‐grade welding capabilities and precision machining and fabrication services under one roof.

- Multiple high‐capacity overhead cranes for material movement between bays

- Oversized door truck access to fabrication and machining bays

- Sheet and plate metal rolling, shearing and braking

- Large capacity stress relief oven

- CNC shape cutting, plasma & oxy‐fuel

Get a Quote!

We specialize in providing tailored solutions for all your welding needs, including custom-built welding tables. Our team of skilled artisans combines expertise with innovation to deliver top-quality, durable welding tables that are tailored to your specifications. Whether you require a specific size to fit the footprint in your existing warehouse or into your home workshop, we're here to turn your vision into reality. From hobbyists to professionals, we cater to all levels of welding enthusiasts, ensuring that each table we create is built to withstand the rigors of your projects while enhancing your workflow. Get in touch with us today for a quote and take the first step towards owning a welding table that's as unique as your craftsmanship.

Contact Us

Street Address: 11 Industrial Blvd. | Sauk Rapids, MN 56379 USA

Phone: 320.253.2699 | Fax: 320.253.4804

Sales-Related Inquiries: 320-253-2699 | Email: sales@c4weld.com

Human Resources-related Inquiries: 320-253-2699 | Email: hr@c4weld.com

Hours of Operation: Monday – Friday: 8:00am – 4:00pm

Tell Us How We Can Help!

ISO 9001:2015 Certified Quality Systems

Street Address: 11 Industrial Blvd.

Sauk Rapids, MN 56379 USA

Main Phone: 320.253.2699

Fax: 320.253.4804

Sales-Related Inquiries: 320-253-2699

Email: sales@c4weld.com

Human Resources-related Inquiries:

320-253-2699 Email: hr@c4weld.com