Testing & Inspection Services

Welding Inspection By AWS Certified Inspectors

Quality is the highest priority for us. This is demonstrated by having American Welding Society (AWS) Certified Weld Inspectors (CWI) on staff. The benefits of doing so include the following: the ability to conduct in‐process inspections both during welding cycles and at critical control points; and the opportunity to document findings throughout the process.

We can provide documentation at any point during the process to validate that the product is being manufactured to the drawings and specifications provided.

Proactive Non-Destructive Testing

We operate well‐managed programs that ensures top‐quality results. The following are Non-Destructive tests performed onsite or in‐house:

Magnetic Particle (MT)

By running a magnetic current to find flaws and cracks on the surface and near-surface of ferromagnetic materials

Liquid Penetrant (PT)

Produces flaw indications with liquid colored or fluorescent dyes

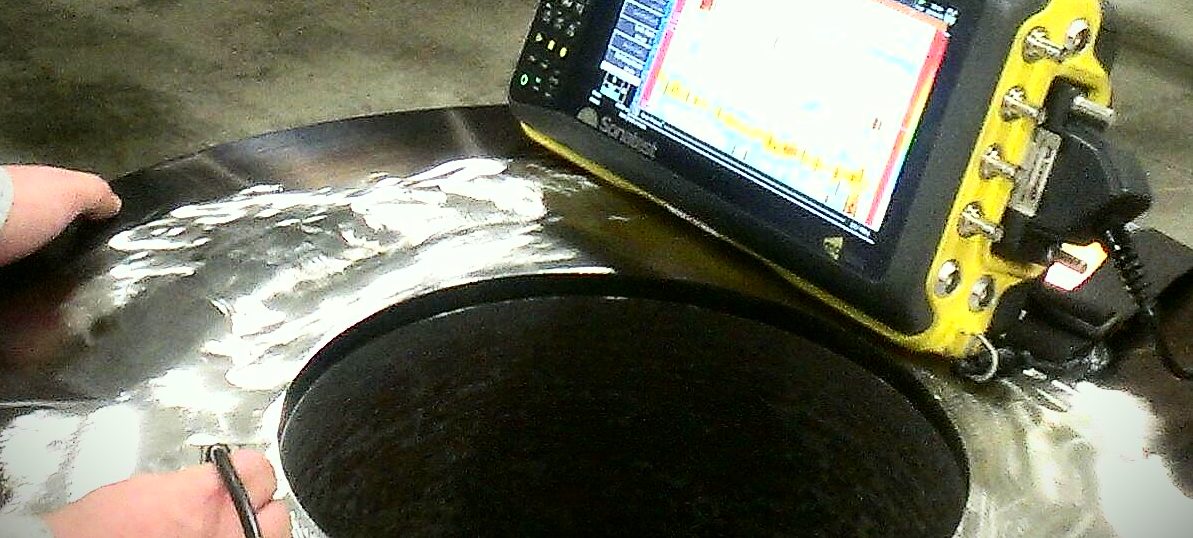

Ultrasonic Test (UT)

Using special equipment to create high frequency sound waves to penetrate material thickness

Visual Test (VT)

Trained visual inspectors use their knowledge, designs and product documents for inspections using their vision

Other testing

Functional, Hydro, and Proof Testing

Quality Systems

Our facility, welding engineers and certified welders have the highest certifications.

Standard for Non-Pressure Vessel Applications

Our Standard quality program is qualified to MIL‐I‐45208 and is ISO 9001:2015 certified.

ASME for Pressure Vessels

Our manufacturing facility conforms American Society of Mechanical Engineers Section VIII, Division I (ASME “U” Stamp) for in shop and field fabrication of pressure vessels. “U” Stamped Vessels are altered and repaired in accordance with the National Board Inspection Code (NBIC “R” Stamp).

Certificates of Authorization

- “NB” Mark (National Board)

- “U” Stamp; “R” Stamp.

Tell us About Your Next Project

Our dedicated and knowledgeable team’s welding, machining and manufacturing experiences allows us to manage and build your projects on time while keeping your specifications in mind.

Ready to begin?

Value Engineering

Cost-Reduction Analysis & Design

Critical Welding

National Reputation for Weld Excellence

Performance Testing

Products Tested to Expected Performance

NDE Inspection

Evaluation without affecting serviceability

Need More Information?

We specialize in providing tailored solutions for all your welding needs. Our team of skilled artisans combines expertise with innovation to deliver top-quality, durable welding tables that are tailored to your specifications. Whether you require a specific size to fit the footprint in your existing warehouse or into your home workshop, we're here to turn your vision into reality. From hobbyists to professionals, we cater to all levels of welding enthusiasts, ensuring that each table we create is built to withstand the rigors of your projects while enhancing your workflow. Get in touch with us today for a quote and take the first step towards owning a welding table that's as unique as your craftsmanship.

Contact Us

Street Address: 11 Industrial Blvd. | Sauk Rapids, MN 56379 USA

Phone: 320.253.2699 | Fax: 320.253.4804

Sales-Related Inquiries: 320-253-2699 | Email: sales@c4weld.com

Human Resources-related Inquiries: 320-253-2699 | Email: hr@c4weld.com

Hours of Operation: Monday – Friday: 8:00am – 4:00pm

Tell Us How We Can Help!

ISO 9001:2015 Certified Quality Systems

Street Address: 11 Industrial Blvd.

Sauk Rapids, MN 56379 USA

Main Phone: 320.253.2699

Fax: 320.253.4804

Sales-Related Inquiries: 320-253-2699

Email: sales@c4weld.com

Human Resources-related Inquiries:

320-253-2699 Email: hr@c4weld.com